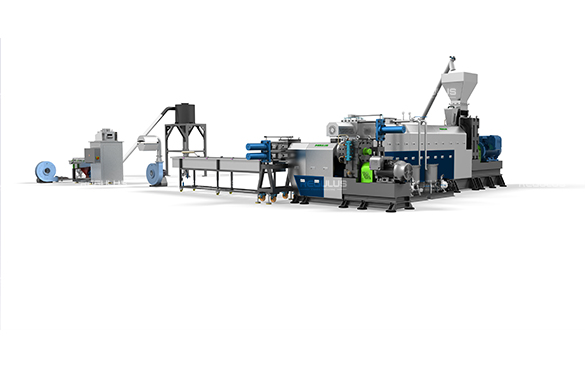

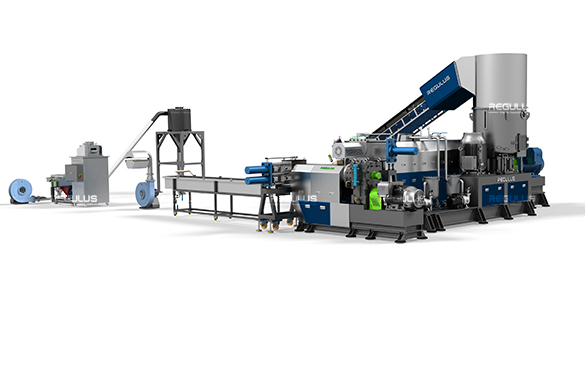

Pet Pp pet filcy Concaction Score State Recyculing ndi Mzere wopanga ma granation

Kulembana

| Chandamale chobwezeredwa | Hdpe, lp, bopp, cpp, trespor, pa, PC, PS, PE, PE, Abs | |||||

| Kachitidwe kachitidwe | Lamba wonyamula, kudula ma compactor, screw screpler, kusefa,Chilesi, Chipangizo chozizira madzi, gawo lamphamvu kwambiri, fan yopanga, silo yamalonda. | |||||

| Zinthu za screw | 38crmoala (sitem-645), bimetalil (posankha) | |||||

| L / d | 28/1, 30/1, 33, (Malinga ndi Zomwe Mungakonzenso) | |||||

| Mchiritso wa mbiya | Chotenthetsera kapena chotenthetsera kwambiri | |||||

| Kuzizira kwa mbiya | Kuzizira kwa mafani kudzera pamimba | |||||

| Mtundu wa Pellet | Madzi oyipitsitsa a madzi / madzi opindika / pansi pa madzi | |||||

| Ntchito zaukadaulo | Kapangidwe ka polojekiti, kapangidwe ka fakitale, kukhazikitsa ndi malingaliro, kutumiza | |||||

| Model Model | Kongoletsa | L / d | Screw screpler | |||

| Mabuku | Mphamvu yamoto | Screw m'mimba | Moto wa Expreser | Kutulutsa mphamvu | ||

| (Lita) | (kw) | (mm) | (kw) | (kg / h) | ||

| Xy-85 | 350 | 37 | 85 | 33 | 55 | 150-250 |

| Xy-100 | 500 | 55 | 100 | 33 | 90 | 250-350 |

| Xy-130 | 80 | 90 | Wakwanitsa | 33 | 132 | 450-550 |

| Xy-160 | 1100 | 110-132 | 160 | 33 | 185 | 650-800 |

| Xy-180 | 1500 | 185 | 180 | 33 | 250-280 | 900-1100 |

Cutter comproct pulasitiki yobwezeretsanso dongosolo

Zowerengekazo zimapanga ndi kupendekera system imaphatikiza ntchito yophwanya, kuphatikizira, ma pulasitiki komanso kupenya gawo limodzi. Imagwiritsidwa ntchito pulasitiki yobwezeretsanso. Dongosolo la aphoto ndi lodalirika komanso lodalirika la filimu ya pulasitiki, Ruffh, matumba, matumba, matumba opatukana ndi makina ogulitsa ndalama zambiri. Itha kupereka zotulutsa zapamwamba koma ndi mphamvu yotsika imasambitsa. Ntchito: Pe, mas, PS, abs, Xps, EPS, PVB.

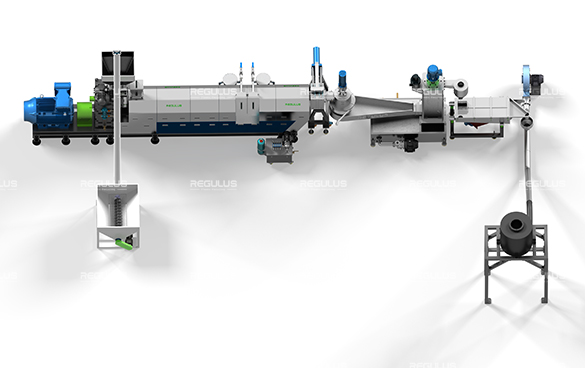

Kudyetsa

Kupanga kofanana, zopindika pulasitiki monga filimu, filimu, rafiya yopezeka m'chipinda cholumikizira kudzera pa lamba; Kusamalira rolls 'scraps, yokulungira ndikuchotsa chipangizocho njira yodyetsa. Magalimoto oyendetsa lamba a lamba ndi kubweretsa chida chokhacho. Kudyetsa liwiro la lamba la lamba kapena mpukutu wotsika kumangochitika mokwanira kutengera chipinda cha comproctor m'chipindacho.

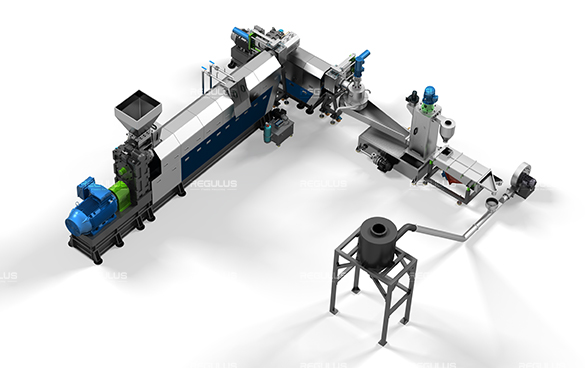

Kuphwanya ndi Kupanga

Ma compactor ali ndi chida chotopetsa. Ndi ntchito yamakina ya mpeni wa rotor ndi mpeni wopondera pansi, kutentha kwa ma compactoctor ndi zinthu kumawonjezeka pang'onopang'ono kudula komanso kukangana ndi fumbi pa rawpoctor. Chipangizocho chimatha kuchotsa chinyezi ndi fumbi, lomwe limapewa kugwiritsa ntchito mankhwala owonjezera kuthana ndi chinyezi.njira yodyetsera.

Masamba a zovota a compactor

Mbewu yozungulira ndi tsamba lokhazikika kudula zomwe zili m'mafunde ang'onoang'ono. Kutentha kwamatsenga komwe kumapangidwa ndi masamba othamanga kwambiri adzatentha ndikusintha ma flake.

Screw screpler

Mapulogalamu athu apadera a kapangidwe kake kakang'ono kwambiri amatulutsa mapulufungeni ndi ma pulasitiki. Tife achitsulo otayika ali ndi vuto lalikulu lotsutsa, kuvala nthawi yayitali komanso yayitali.

Ma cell ocheperako

Ndi malo ochulukitsa kawiri monga ma molekyulu ndi chinyezi zimachotsedwa bwino kuti zithandizire ma granules, makamaka makamaka pazovala zolemera.

Mlangizi wa Plate

Fyuluta yamtundu wa mbale imapangidwa mu mtundu wopitilira ndi mbale ziwiri zosefera. Pali fyuluta imodzi yomwe ikugwira ntchito ngati chophimba chikusintha.

Palibe cholembera choyimira

1.A (piston yokhazikika-screen ya screen kapena yopanda ma statele state / piston anayi-station yomwe ikhoza kuyikidwa pamutu wakuthwa kuti mupange magwiridwe antchito.

2.Long Screen nthawi yonse yosintha, kusintha kwapafupipafupi kusintha: Kawirika kanthawi kochepa chifukwa cha malo akulu osefera.

3. Yosavuta kugwiritsa ntchito mtundu wa sinayime: Kusintha kosavuta komanso kosasunthika ndikusafunikira kuyimitsa makinawo.

4. Vomberani wochepera.

Makina ofukula mphete

1. Kudzipatula Mutu wa Pelletizin kuti muchite bwino kwambiri komanso nthawi yayitali Tikuthokoza nthawi zonse.

2. RPM ya masamba ovota ndi okhawokha ozikidwa pa kusungunuka.

3.veasy ndi FASTTOTER HAFDES APACTOCTOS, popanda kusintha kwa kusintha kwa nthawi.

Makina opingasa amkati

1. Kudzipatula Mutu wa Pelletizin kuti muchite bwino kwambiri komanso nthawi yayitali Tikuthokoza nthawi zonse.

2. RPM ya masamba ovota ndi okhawokha ozikidwa pa kusungunuka.

3.veasy ndi FASTTOTER HAFDES APACTOCTOS, popanda kusintha kwa kusintha kwa nthawi.

Kugwedeza

Kusaka kwa madzi 1.

2. Kusanja kwa GAWI: Mavesi amakhazikitsidwa ndikukhazikika m'malo momata, kuti musinthe miveyo mosavuta mtsogolo.

Derting tinthu dehyditor

Amagwiritsidwa ntchito mwapadera kununkhira kwa pulasitiki yamagetsi ndi kudula tinthu tating'onoting'ono tinthu tating'onoting'ono tinthu tating'onoting'ono tomwe timadula,

chophimba

Ankalekanitsa kukula kwa tinthu ta pulasitiki